MEGASLAB’s concrete technology provides a rebar-free alternative that enhances safety, simplifies installation, and cuts costs—addressing key challenges in the construction process. MEGASLAB is leading the way with a smarter, more efficient approach to concrete that’s transforming how slabs are built.

Eliminating the Need for Rebar

Traditionally, concrete slabs rely on rebar (reinforcing bars) to provide structural support. While rebar has long been essential in reinforcing the concrete, MEGASLAB’s advanced concrete technology eliminates the need for this material altogether. Through innovative engineering and unique material compositions, MEGASLAB’s slabs are designed to provide the same durability and strength that rebar-reinforced concrete delivers—without the additional material and labor costs associated with rebar installation.

Safer Working Environment

One of the most significant advantages of slabs without rebar is the creation of a safer working environment. Rebar installation can be hazardous for workers, with the potential for cuts, punctures, trips and falls and other injuries caused by exposed steel bars. Additionally, the heavy lifting and manipulation of rebar increases the risk of physical strain and accidents on construction sites.

MEGASLAB’s technology removes the need for rebar, reducing the amount of physical labor required on-site and minimizing exposure to sharp, potentially dangerous materials. This results in fewer accidents, a safer environment for workers, and a reduction in the need for personal protective equipment, which can further streamline operations.

Easier and Faster Installation

Installing traditional concrete slabs with rebar can be time-consuming and labor-intensive. Workers must spend significant time bending, positioning, and securing the rebar before pouring the concrete. This process adds complexity to an already intricate task, which can extend project timelines.

With MEGASLAB’s rebar-free slabs, installation becomes simpler and faster. The absence of rebar reduces the number of steps needed to prepare the concrete, allowing for quicker project completion and a smoother workflow. Contractors can focus on other aspects of the project, minimizing downtime and accelerating construction schedules.

Eliminating the Cost of Rebar

In today’s economy, one of the biggest challenges facing construction companies is the rising cost of materials. Rebar, often imported from overseas, is subject to unpredictable price fluctuations due to global supply chain disruptions, tariffs, and shipping delays. These increasing costs can have a significant impact on project budgets and timelines.

By eliminating the need for rebar, MEGASLAB offers a cost-effective alternative that helps construction companies avoid these financial pressures. Not only do you save on the cost of purchasing and importing rebar, but you also reduce the labor costs associated with its installation. In a market where every dollar counts, this is a crucial benefit that can help keep projects within budget and on schedule.

Tariff-Free Construction

The importation of rebar involves tariffs and import taxes that can significantly increase costs for construction projects. As global trade relations shift and tariffs fluctuate, the price of rebar imported from overseas can become unpredictable. MEGASLAB’s technology eliminates the need for rebar imports entirely, allowing construction companies to avoid these additional costs and supply chain disruptions. This makes projects more financially predictable and less vulnerable to global economic shifts.

Environmental and Sustainability Benefits

Beyond the direct financial and safety advantages, eliminating rebar also has significant environmental benefits. The production and transportation of rebar contribute to carbon emissions, from mining raw materials to the energy-intensive manufacturing processes and shipping. By using rebar-free slabs, MEGASLAB reduces the overall carbon footprint of construction projects.

Furthermore, the simplified manufacturing and installation processes contribute to more sustainable building practices. Fewer materials are required, and less energy is expended on-site, making the entire construction process more eco-friendly.

Case Study: Yancey Bros. Parking Lot Expansion with MEGASLAB®

Project Overview:

Client: Yancey Bros., premier CAT® dealer in Georgia

Location: Austell, GA

Project Size: 94,000 SF parking lot expansion

Year: 2022

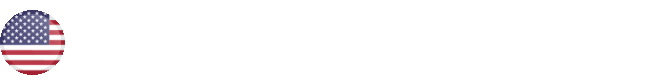

Original Design:

12″ heavy-duty concrete pavement

Double mat of rebar

Designed to withstand steel track CAT machines

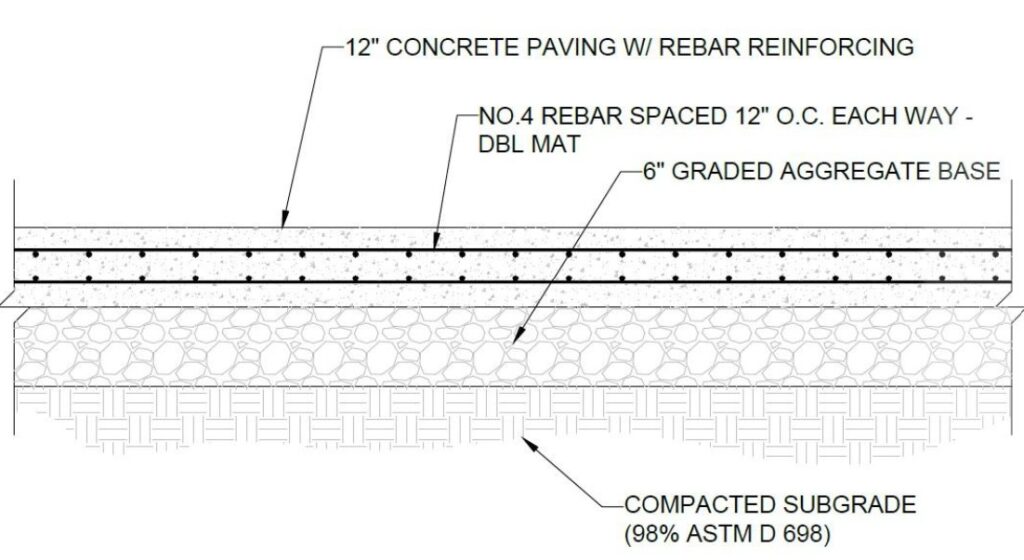

MEGASLAB® Solution:

Optimized Mix Design to enhance performance

Subgrade Improvements for better load-bearing capacity

Specialized Admixture & Fiber Blend for strength & durability

Thinner Slab: Reduced thickness by 3″

Rebar Elimination: Removed 145 TN of rebar

Key Benefits:

Cost Savings: Reduced labor and material expenses

Faster Installation: Completed ahead of schedule

Increased Durability: More resilient slab

Sustainability Impact:

75% Embodied CO₂ Reduction (partially due to rebar elimination)

Conclusion:

MEGASLAB® delivered a more efficient, cost-effective, and eco-friendly solution while maintaining the durability required for heavy-duty equipment storage.

Final Thoughts

Slabs without rebar represent a major leap forward in construction technology, offering a host of benefits that address safety concerns, improve efficiency, reduce costs, and mitigate tariff-related challenges. MEGASLAB’s innovative concrete technology provides a robust, rebar-free alternative that is not only safer and easier to install but also helps eliminate the unpredictable costs of importing rebar.

In an industry that is constantly seeking ways to improve, MEGASLAB’s solution offers a smarter, more sustainable way to build. As construction projects become increasingly complex and budgets tighten, making the switch to rebar-free slabs could be the key to staying competitive and ensuring successful project completion.

For contractors and developers looking to streamline their operations and reduce costs, MEGASLAB’s rebar-free slabs provide a forward-thinking solution that ensures high-quality, cost-effective, and efficient construction.