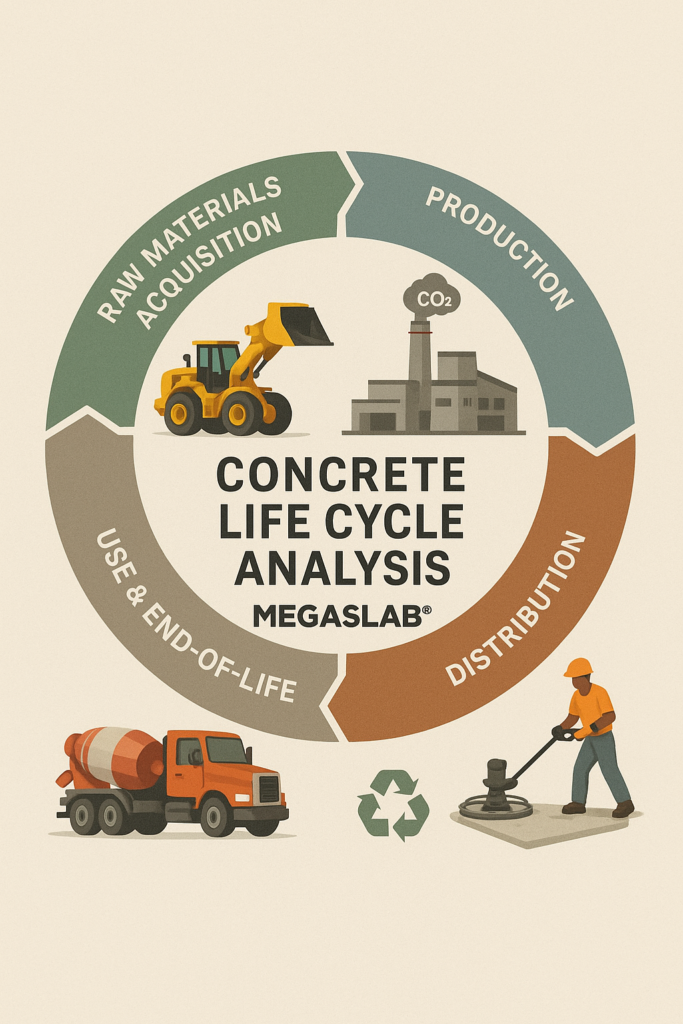

As global industries shift toward sustainability, the concrete construction sector – especially in pavements and slab systems – is under increasing pressure to reduce environmental impacts. Life Cycle Analysis (LCA) is emerging as a critical method to quantify and minimize the long-term ecological footprint of these structures. Companies like MEGASLAB, which specialize in advanced slab systems, are leading the way by incorporating LCA into their design and production processes.

What Is Life Cycle Analysis in Concrete Construction?

LCA is a scientific, data-driven process that evaluates the total environmental impact of a material or system across its entire lifespan. In pavement and slab concrete construction, this includes:

- Raw Material Sourcing – Impacts from mining cement, aggregates, and admixtures.

- Manufacturing – Energy use and emissions in producing concrete and reinforcement.

- Transportation – Emissions from moving materials to the construction site.

- Installation – Energy, equipment use, and waste generation during pouring and curing.

- Use Phase – Performance over time, including heat island effect, maintenance frequency, and energy reflection.

- End-of-Life – Demolition, recycling, or landfilling of slab materials.

This full-spectrum view empowers engineers, contractors, and developers to make smarter, greener decisions that impact both project economics and long-term sustainability.

Why It Matters in Pavement and Slab Applications

Slabs and pavements are often overlooked in sustainability discussions, yet they cover immense surface areas and consume massive volumes of concrete. Integrating LCA into this sector offers several key benefits:

- Reduced Embodied Carbon

- Concrete is responsible for approximately 8% of global CO₂ emissions. By leveraging LCA, builders can choose lower-impact materials, optimize slab thickness, and adopt high-performance alternatives—like MEGASLAB’s high-strength, fiber-reinforced concrete—reducing material volume and carbon footprint.

- Improved Durability and Lifespan

- LCA highlights the long-term performance of slab systems. MEGASLAB, for example, provides slabs with superior crack resistance and flexural strength, which reduces the frequency of repairs and replacements, cutting down on resource consumption over time.

- Maintenance and Operational Savings

- The use phase of concrete slabs includes maintenance, energy absorption, and even contribution to surface temperatures. Slabs with reflective properties or fewer joints, like MEGASLAB’s jointless system, can improve operational efficiency and reduce maintenance needs—key data points captured in a full LCA.

- Optimized End-of-Life Decisions

- An effective LCA considers how easily a slab can be deconstructed, recycled, or reused. Advanced concrete systems designed for recyclability reduce landfill waste and promote circular construction principles.

MEGASLAB: A Practical Example of LCA in Action

MEGASLAB’s engineered slab system is a benchmark for sustainable concrete technology. Designed to outperform traditional slab-on-grade solutions, MEGASLAB uses a proprietary mix design that reduces cement content, incorporates industrial byproducts (like fly ash or slag), and minimizes slab thickness without sacrificing strength.

Through its use of LCA, MEGASLAB demonstrates:

- Lower embodied carbon per square foot of slab

- Fewer joints, which reduces long-term repair and material needs

- Increased durability, reducing lifecycle costs

- Design adaptability to support sustainable site layouts and lighter foundations

By integrating environmental assessment tools and quantifying impacts at each life stage, MEGASLAB can deliver both environmental transparency and long-term value.

Future of LCA in Concrete Infrastructure

As regulations tighten around carbon disclosure and ESG reporting, pavement and slab projects that don’t incorporate LCA may face both compliance and marketability challenges. Tools are now emerging to pair LCA with Building Information Modeling (BIM), enabling more dynamic assessments during early-stage design.

For firms adopting LCA, it’s not just about reducing environmental impact—it’s about staying competitive, reducing costs over time, and meeting the evolving demands of sustainable infrastructure development.

Conclusion

Life Cycle Analysis is no longer optional for the future of pavement and slab concrete construction. It is a fundamental part of building smarter, more resilient, and environmentally conscious infrastructure. Companies like MEGASLAB demonstrate how embracing LCA from the start can lead to meaningful reductions in environmental impact—while improving performance and cost-efficiency.

As concrete remains the backbone of modern infrastructure, the road to sustainability starts with analyzing every slab we pour.